World-class Cancer Care Made Possible Through Complex Construction

When BAMF Health opens in June 2022 in the Doug Meijer Medical Innovation Building on the Medical Mile in Grand Rapids, it will be home to the world’s most advanced molecular imaging clinic, radiopharmacy and theranostics clinic, providing world-class health treatment for various types of cancer, Alzheimer’s, Parkinson’s, cardiac disease and much more.

BAMF Health’s life-changing treatments are part of a new field called theranostics, which uses novel tracers to identify and treat various conditions. These treatments use radioactive isotopes, which must be carefully produced and controlled.

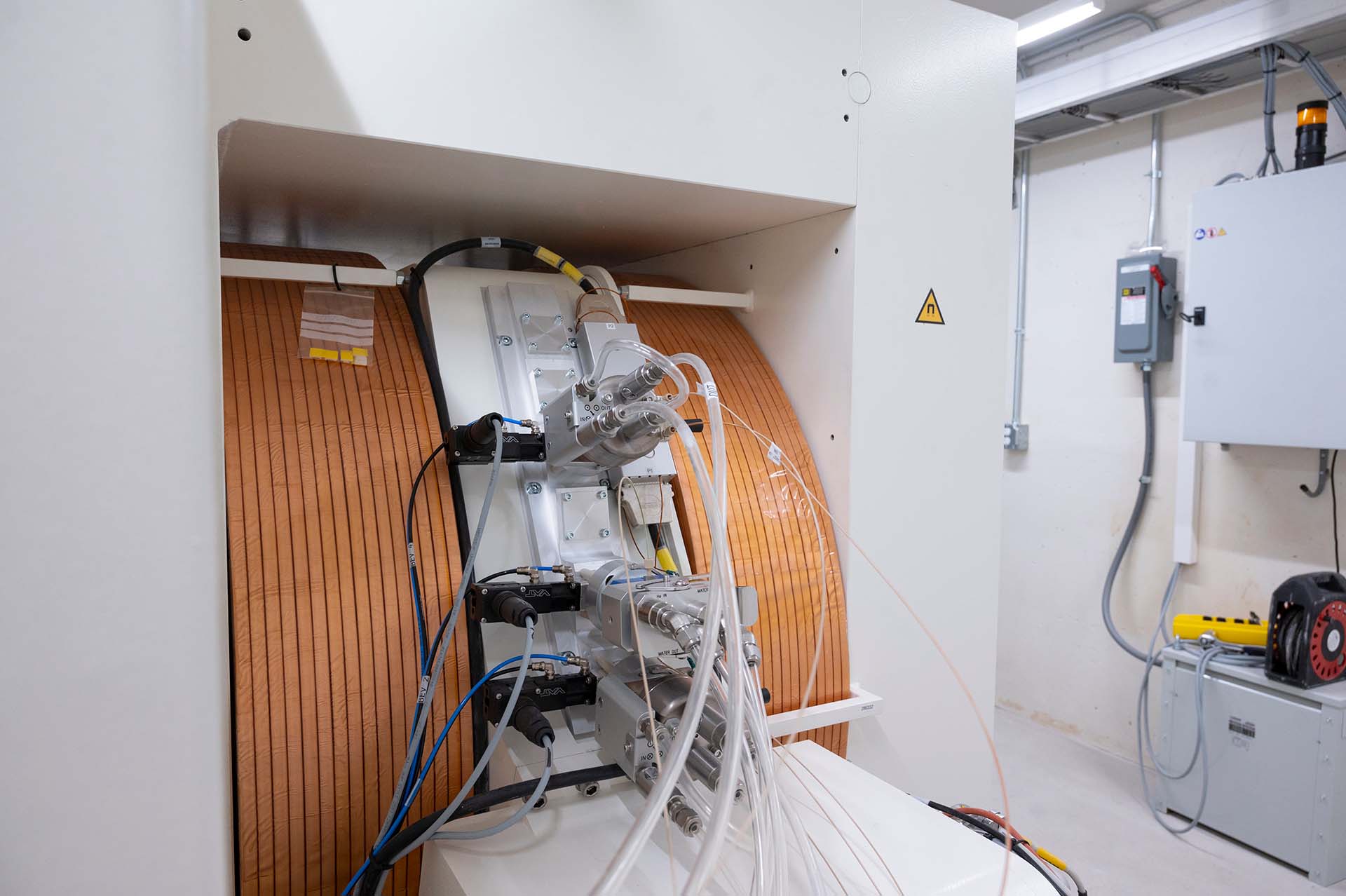

Cyclotrons produce the radioisotopes needed for BAMF Health’s novel care by propelling a beam of charged particles at a target composed by a stable isotope. When they interact, a radioisotope is created. This process requires shielding and a specialized facility, including custom cyclotron vault housings and a custom exhaust system to ensure the process is properly contained.

For Steve McGovern and Mark VanderVeen, superintendents at Rockford Construction, who is building the facility in a joint venture with Walsh Construction, the technically difficult aspects of this project meant weeks of advanced planning and sophisticated building modeling.

From the design phase, Rockford experts used BIM, or building information modeling, to create a detailed and specific virtual rendering of the building to ensure that all aspects of the construction would be accounted for in the complex design of the cyclotron vault systems.

“On a project of this complexity, where the vault ceilings were within feet of the structural beams for the second floor, using BIM was absolutely critical,” McGovern said. “This was a very complex and challenging project. Having everything planned well in advance and thinking about all of the variables took several weeks of hard work and planning with experts and vendors from all over the world.”

Because the vaults contain radiation, they needed to be built with six-foot-thick concrete walls. Specialty doors that can contain the radiation were shipped from Italy. The cyclotrons came from overseas as well.

“The whole execution of the vault system was challenging, but we knew we had the resources to do it,” VanderVeen said. “Even things as simple as electrical conduit had to be absolutely perfect to make sure power supplies to the cyclotrons were exactly where they needed to be.”

Other challenges included keeping up with an aggressive schedule. Erection of the building’s steel support beams had to be done in two phases so the beams wouldn’t interfere with the pouring of the vault’s massive walls or the installation of its roof. The roof’s rebar supports were assembled onsite and then craned into place before the roof could be poured. Logistics had to be planned without error.

The building also features complex ventilation and exhaust systems that sit below ground level, including a system called a “delay maze” that directs exhaust airflow through a large volume labyrinth before delivering it to the HVAC system.

All of this work is happening on a tight, urban site where three separate projects are taking place. Rockford is finalizing the Doug Meijer Medical Innovation Building for Michigan State, completing the outfitting for BAMF Health’s space and building a global headquarters for another tenant, all on the same site at the same time. This takes an incredible amount of logistics and planning to coordinate site access and the great number of tradespeople who work on site.

“We have the experience and great trade partners on our side to make difficult builds look easy,” McGovern said. “Even challenging projects can get done perfectly when planning and execution match up on site.”

previous Post

previous Post